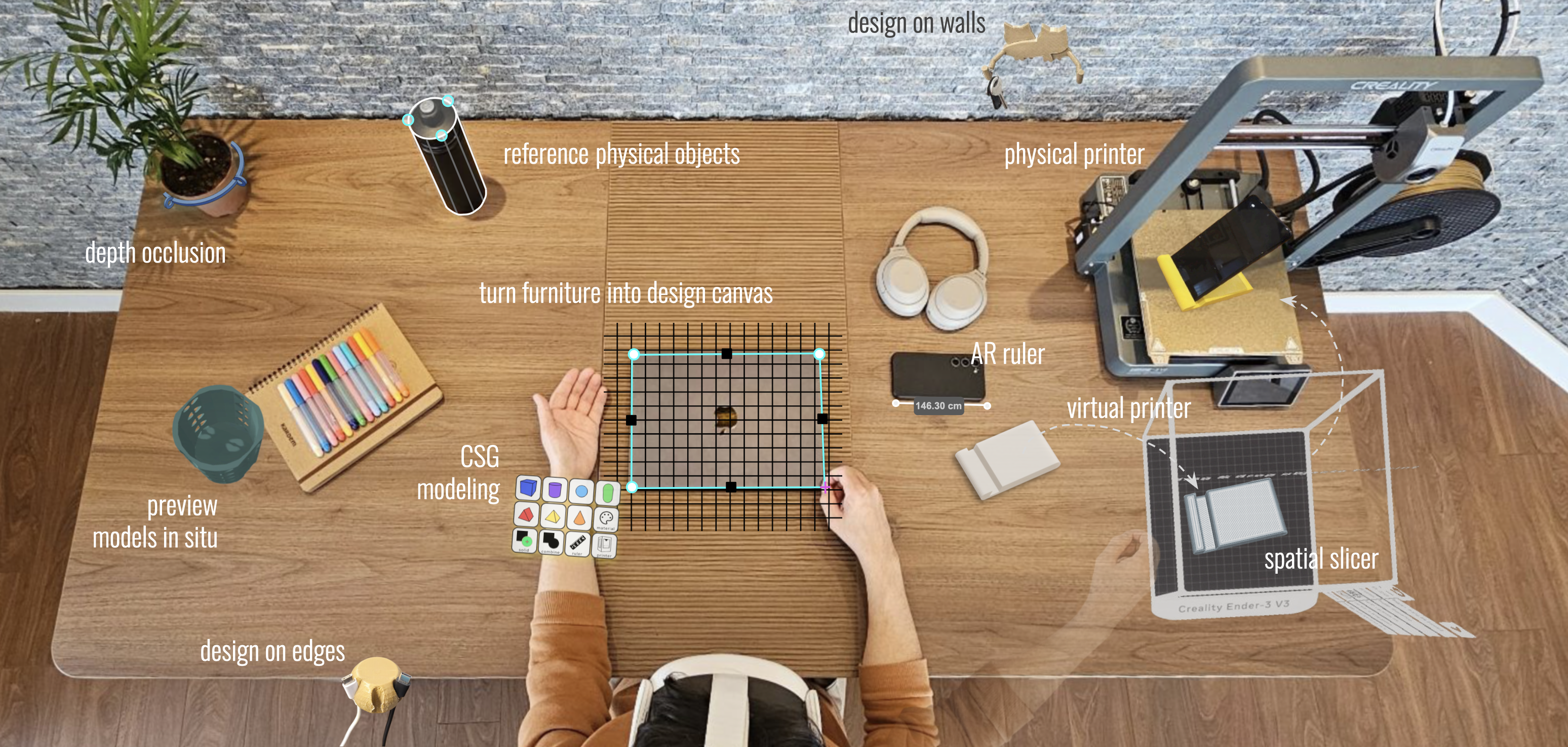

Key Features of TinkerXR

TinkerXR enables in-situ CAD and 3D printing in AR. The system features spatial awareness, depth occlusion, and use of physical objects and constraints for design. With Constructive Solid Geometry modeling, users can convert surfaces into interactive design canvases and interact with 3D printers' digital twins to prepare and initiate fabrication.

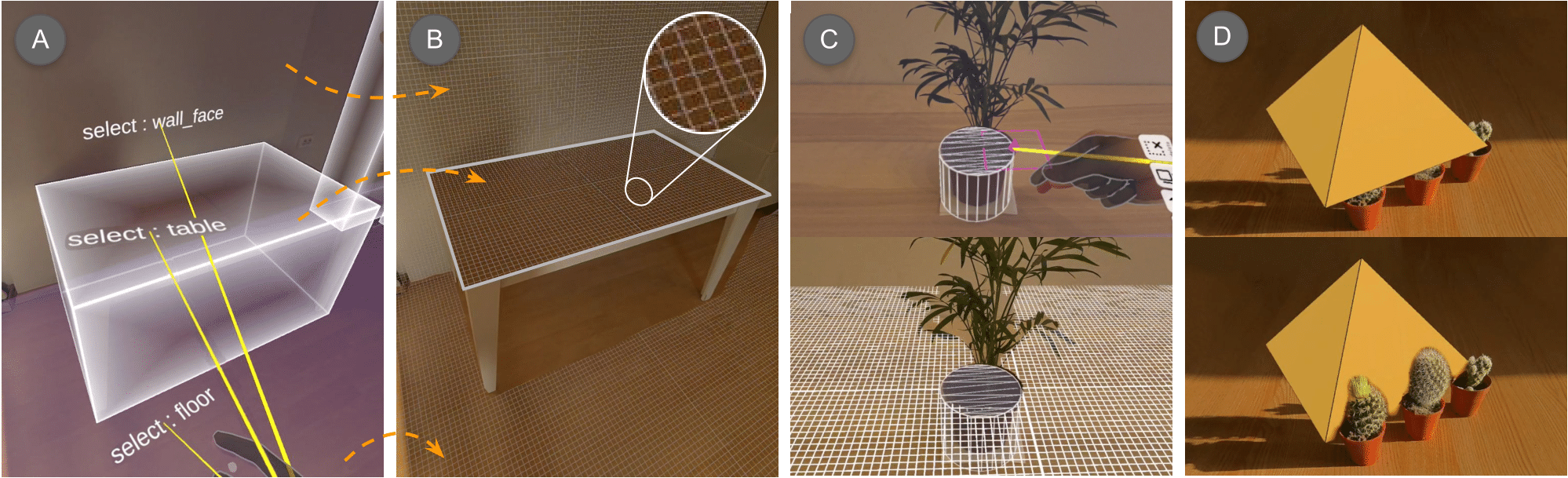

Spatial Awareness

Advanced spatial understanding allows TinkerXR to recognize and adapt to real-world environments, enabling context-aware design directly on physical surfaces.

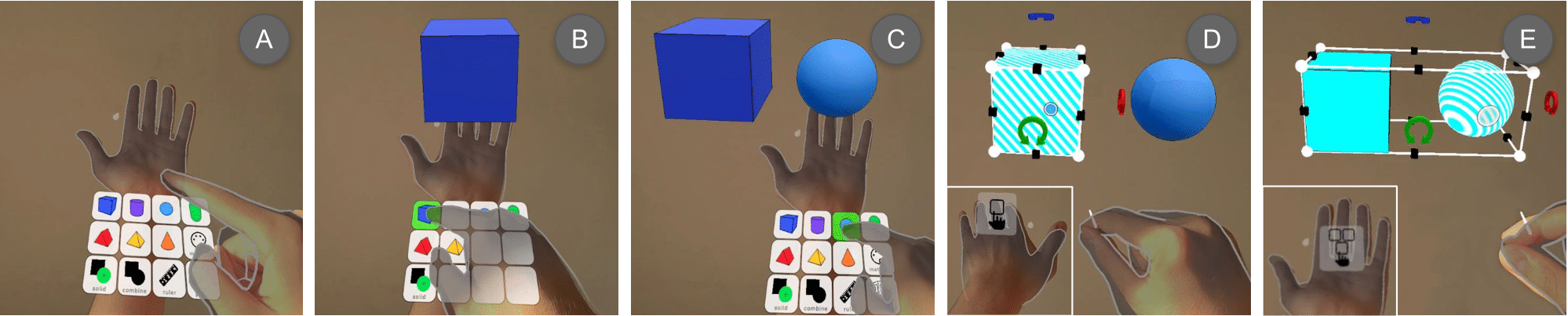

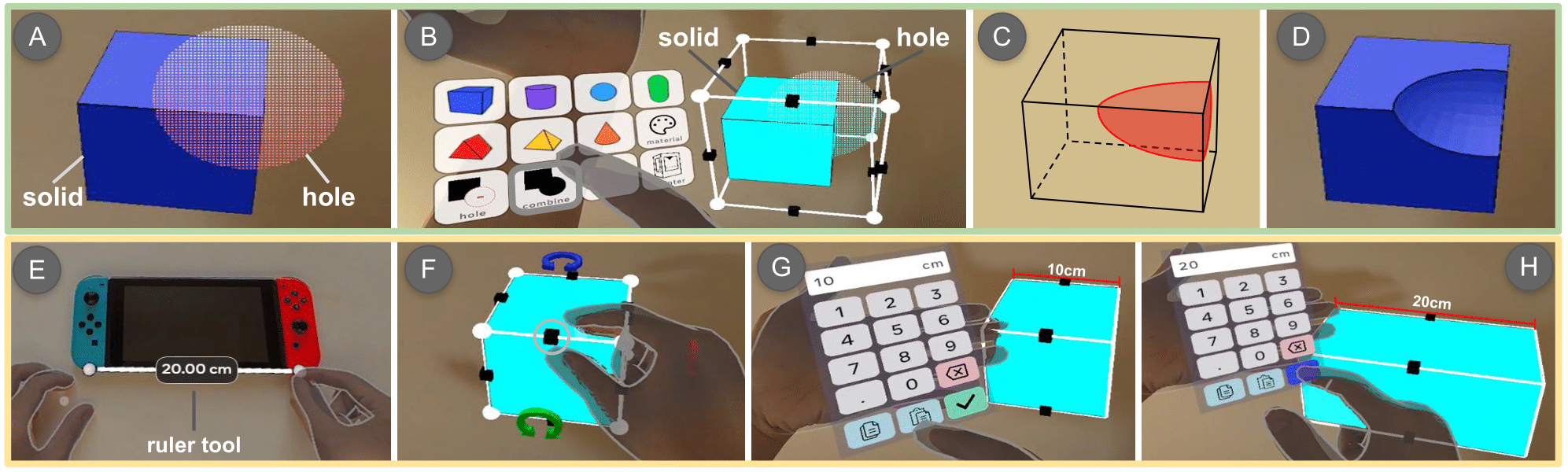

Creating Objects

Intuitive object creation using hand gestures and Constructive Solid Geometry (CSG) primitives for building complex 3D models in AR space.

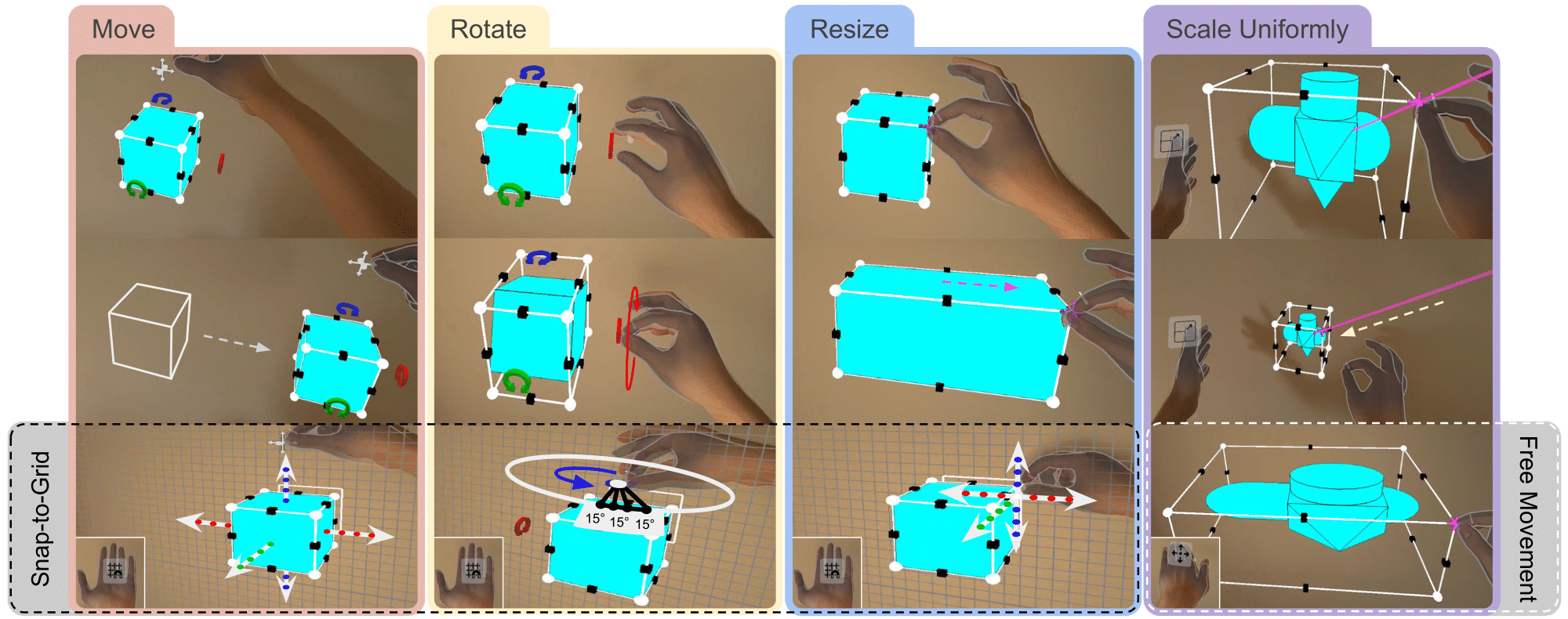

Object Manipulation Schema

Comprehensive interaction framework for manipulating 3D objects including translation, rotation, scaling, and Boolean operations in augmented reality.

Precision Measurement

Precision measurement tools and object combination workflows that enable accurate design and assembly of complex structures.

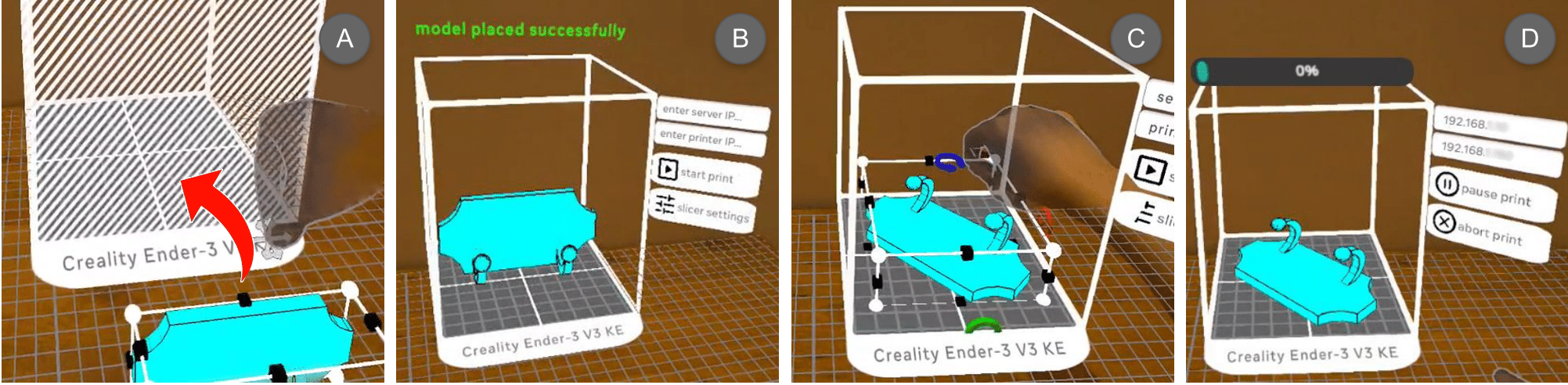

Integrated 3D Printing Workflow

TinkerXR integrates design with fabrication through a drag-and-drop interface for 3D printer virtual twins. The system includes built-in slicing capabilities and allows users to initiate printing directly from the AR interface, enabling the transition from digital design to physical creation.

3D Printer Integration

Direct integration with 3D printers through virtual twins enables fabrication workflow from AR design to physical output with drag-and-drop simplicity.

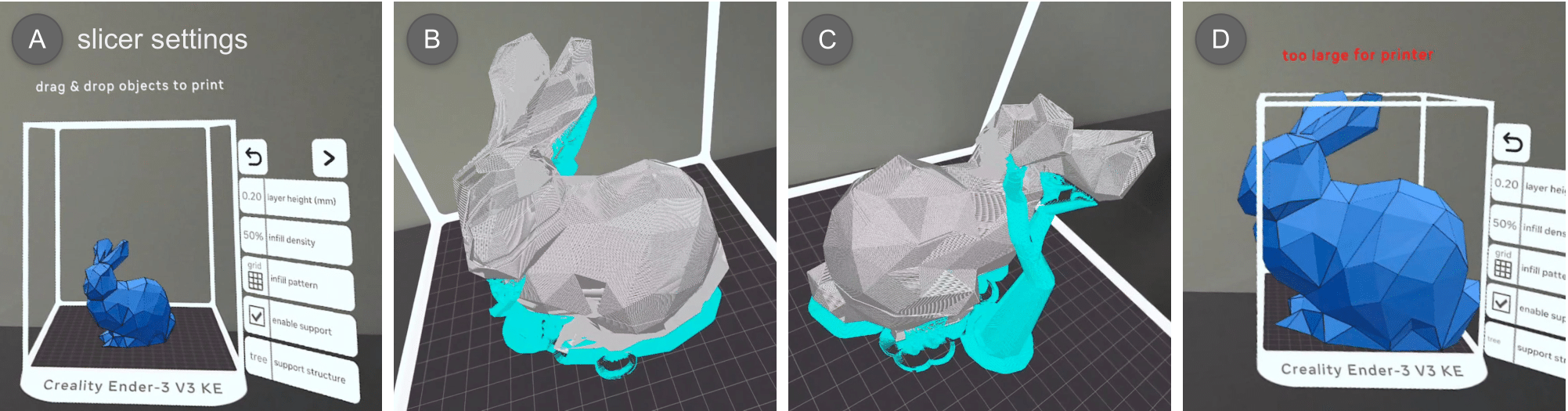

Slicing

Built-in slicing functionality allows users to prepare models for 3D printing directly within the AR interface, simplifying the fabrication workflow.